In the ever-evolving world of poultry feed production, daily challenges are plentiful, threatening efficiency and profitability. But fear not! This blog unveils the game-changing solution. Discover how this innovative technology tackles poultry feed mill problems, inventory woes, harnesses data for smarter decisions, optimizes formulations, forecasts feed needs, and streamlines procurement. Join the revolution with Livine and take your poultry farm to new heights. Don't miss out on the chance to revolutionize your operations and seize your competitive edge.

Published 01 Mar 2024

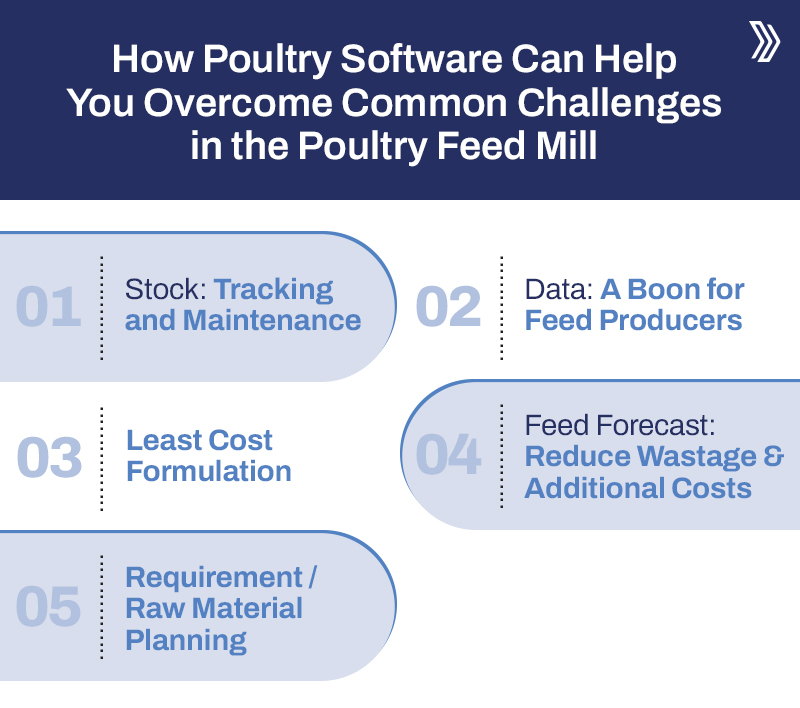

How Poultry Software Can Help You Overcome Common Challenges in the Poultry Feed Mill

Poultry feed producers face constant challenges to struggle as feed processing becomes a more challenging task than ever. From ingredient price volatility in basic feed ingredients, and newer raw materials to improving technology to increasing demand to meet the needs of the world population. Things just don’t seem to get simpler for feed producers.

Running an efficient, profitable feed mill is tougher than ever. While these challenges come with their own consequences, technological advancements have allowed feed producers to solve these challenges, one at a time. However, the right feed mill management software can help solve persistent issues.

This blog post explores key difficulties feed mills encounter and how an integrated feed mill management system levels up operations. So, let’s look at some of these challenges and how a feed mill software solution can be the deal breaker in terms of improved productivity in poultry production.

Tracking and Maintaining Vital Stock Inventory

For poultry feed producers, keeping a well-maintained inventory of raw materials required for feed formulation plays an important role. Careful tracking of ingredient stock levels allows better planning of pre-orders and production. A feed mill management software detects moisture or spills, preventing lost inventory, and allowing the producers to plan at a pre-order level for their feed.

Additionally, an integrated poultry management software can help detect and capture excessive moisture or any form of leakage in the inventory, preventing additional losses.

Harnessing Data for Smarter Decisions

Processing thousands of tons daily generates huge data. However, it is very unlikely that every feed producer can track and monitor this amount of available data. This is where poultry software can make a huge difference.

A feed mill inventory management system analyzes this to formulate better ratios. A feed mill management system can track data and allow better feed formulation from the data records available.

- Data analysis also enables better stock maintenance, allowing the feed mill owners to plan production and subsequently plan for the ingredient requirement.

- Feed combination is one of the key factors for a successful feed production process. Historical data guides ideal ingredient combinations to work with.

Dialing in least-cost formulations

At its core, a feed production unit needs to have a least-cost feed formulation defined in order to find the perfect combination of feed ingredients to provide the poultry with a balanced nutrition.

A perfect idea of raw materials is required with pre-order level planning. Improved inventory maintenance and the correct feed combination enable feed mill owners to arrive at the right least-cost feed formulation.

An ERP poultry system examines all factors, like materials pricing and nutrition targets, to determine the most affordable, balanced feed rations. This optimizes the bottom line. With comprehensive poultry management software, analyzing, and monitoring each of these factors becomes a seamless process, resulting in a productive output in terms of least-cost formulation.

Feed Forecast: Reduce Wastage & Additional Costs

Feed production planning is a well-defined process that involves various factors that come into consideration. With the information about bird stock available in Breeder / Broiler / Layer birds, production capacity, feed inventory (based on the bird stock), and the feed intake mapping with standard values defined, feed production can be planned precisely.

A comprehensive feed mill management software like Livine allows precise planning, which results in less wastage and reduced logistical costs for the feed that could go waste due to a lesser shelf life. Precise feed production planning, aligned to bird numbers and intake, minimizes waste generation and logistics costs from expired, unused feed.

Raw Material Procurement Planning

Maintaining a healthy inventory of raw materials required for feed production becomes a cakewalk, if you can track your production requirements easily. With Livine, analyzing and calculating the feed production requirements is easy, allowing owners to plan for the raw materials required.

Analyzing expected feed output calculates the exact ingredients and amounts to order ahead of time. This further maximizes the feed mill’s productivity and profitability. In other words, the poultry feed mill software solution allows feed producers to plan raw material procurement with precision, for improved feed production.

Join the technological revolution driving the next generation of feed manufacturing success.

Ready to unlock the power of digital transformation for lasting profitability? Don't wait any longer! Connect now and propel your poultry farm to new heights of success. Let's make it happen together!

Ready to unlock the power of digital transformation for lasting profitability? Don't wait any longer! Connect now and propel your poultry farm to new heights of success. Let's make it happen together!

Given the nature of the industry, feed manufacturers have always had a plethora of concerns at the center of production, cost & competition. Feed processing has never been a gold mine and it is highly unlikely that it is going to be one soon. Though it is impossible to predict the next big issue for poultry production, staying ahead of the curve and preparing for the worst to come is the way to go.

In the face of endless new poultry production obstacles, no feed mill can afford disjointed, manual processes anymore. The Livine feed mill management software integrates real-time data and planning capabilities to master formulation challenges rather than let them jeopardize operations and returns. The robust capabilities stacked onto a single intuitive platform give feed mills the edge.