In the world of poultry processing, efficiency, and quality are more important than anything else.

Nowadays consumer demands are shifting from traditional solutions to modern solutions, now they are looking for fresh quality poultry products. So poultry processing plants are becoming complex and are facing a number of challenges that require modern innovation solutions.

Livine poultry processing software has the power of modern advanced technology that can bring overall profitability to the company.

The Challenges of Poultry Processing Plant Management

Managing a poultry processing plant is a complex process that requires a lot of coordination, control, and carefulness.

From maintaining strict food safety protocols to ensuring the minimization of waste, Poultry plant managers must navigate a multitude of variables.

Additionally, various factors like labor shortages, changes in demand, and stringent and rigid regulatory requirements add layers of difficulty, further emphasizing the need for advanced purpose-built software solutions.

Embracing Poultry Processing ERP Software: The Key to Optimization

At the core of modern advanced poultry processing lies Enterprise Resource Planning (ERP) software, a complete suite of tools designed to make an organization or system more efficient and effective by employing faster working methods and integrating every aspect of operations.

By adding and consolidating data from all other departments – including procurement, production, inventory management, and distribution – into a centralized system, the cloud poultry ERP software offers total and complete visibility and control.

Livine's Poultry Processing ERP is an advanced platform that empowers processors to maximize efficiency, ensure regulatory compliance, and drive overall growth and profitability to the business. With its intuitive user interface and vigorous functionality, this ERP software revolutionizes the way poultry processing plants operate.

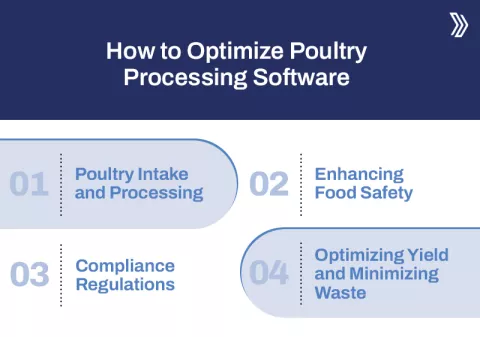

Poultry Intake and Processing: A Seamless Journey

The journey of poultry processing begins with intake, initially a very important as well as a critical stage that sets the tone for the entire operation.

Livine's Poultry Intake and Processing Software simplifies this process by automating data capture by using advanced artificial intelligence and ensuring accurate tracking from the moment the birds arrive at the facility.

Through seamless integration with weighing scales and various scanners, the ERP software captures important data, such as supplier details, lot numbers, and weights, that helps eliminate the potential for human error.

This data is then seamlessly fed into the ERP system, providing real-time visibility and traceability throughout the complete processing chain. To know more you can read this guide to understand better

Enhancing Food Safety and Compliance Regulations

Food safety is non-negotiable in the poultry processing industry, and Livine's software suite excels in this important area.

With built-in Hazard Analysis Critical Control Points (HACCP) and regulatory compliance features, processors can proactively mitigate risks and adhere to strict food safety standards.

Livine software automates monitoring and record-keeping tasks, ensuring that every step of the process shows great attention to detail and is documented so that it can be audited anytime with ease.

From temperature controls to sanitation procedures, plant managers can rest assured that their operations are meeting – and often exceeding – industry benchmarks.

Optimizing Yield and Minimizing Waste

In an industry where margins are slim, maximizing yield and minimizing waste are very important for profitability. Livine's Poultry Processing ERP has advanced modern powerful analytics and reporting capabilities that help in data-driven decision-making.

By analyzing production data, managers can identify inefficiencies that are stopping while creating a seamless process, optimize processes, and implement strategies to reduce waste and improve yield.

Additionally, the software also facilitates accurate inventory management, minimizing spoilage and ensuring that raw materials and finished products are effectively utilized.

Don't lock yourself into narrow software that tries forcing workflows into rigid boxes. See how Livine provides an ever-expanding platform to liberate your enterprise's growth, not inhibit it!